VPG TRANSDUCERS OFFERS A WIDE ASSORTMENT OF ACCESSORIES FOR TRANSDUCERS

VPG Transducers provides comprehensive strain gage installation services that are backed by an ISO 9001-certified quality management system and built on more than 50 years of experience. Our team is able to extend your R&D or engineering team by partnering with you to provide additional expertise and resources. From any high volume R&D prototype sensor to custom installations, rely on our state-of-the-art R&D and production facilities, with qualified technicians to handle whatever your strain gage bonding situation requires.

Challenge: Hand tools designed for torque tensioning applications have limited space for a solution that can inform the user when too much torque is applied. Applying too much torque results in damage to a bolt's screw thread.

Solution: Using a VPG Force Sensors strain gage on a critical component within the hand tool solves this issue, resulting in more productivity and efficiency.

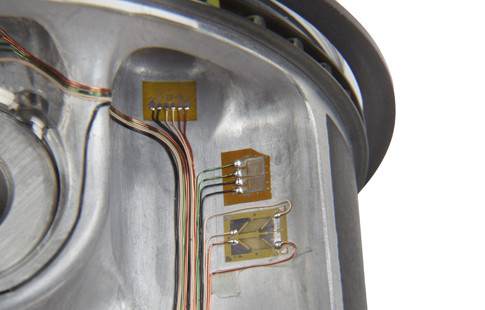

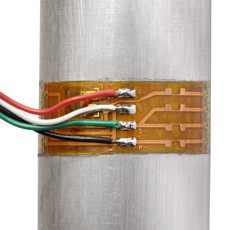

Challenge: X-ray machines are typically heavy, which makes the machine slow and cumbersone to move.

Solution: Custom strain gages can be installed in areas where force is exerted. These gages send a signal to a motor that drives the X-ray machine's wheels, enabling the operator to easily transport the X-ray machine to its destination.

Not all projects require a complex installation. Sometimes a simple, low cost, low volume custom strain gage-based sensor is the answer. VPG Force Sensors is your resource. We can supply the technical support to help you design the perfect solution for your requirement without compromising on quality.

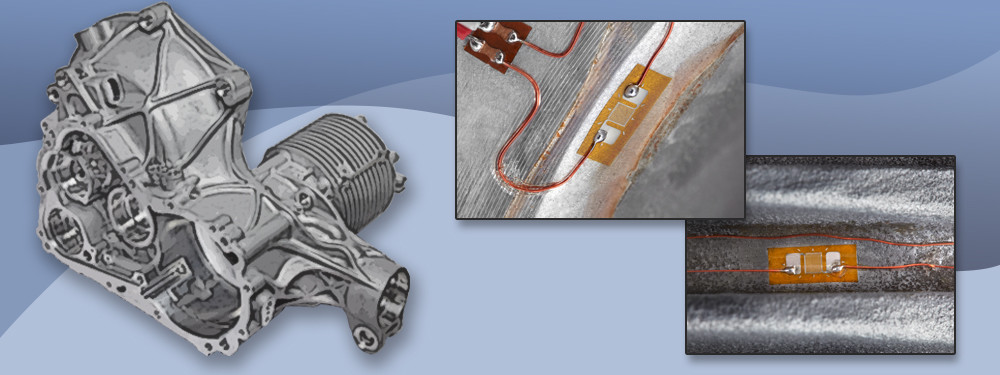

Challenge: Protection is often overlooked when creating a strain measurement solution or custom force sensor. Extreme environments require special installation techniques and materials, including coatings.

Solution: Our experts have the experience to use the appropriate high quality components to protect our installations from harsh environments such as hot oil, salt water, high and low temperatures and mechanical damage. Our strain gage-based solutions have been successfully used from the bottom of the ocean to outer space and many areas in between.

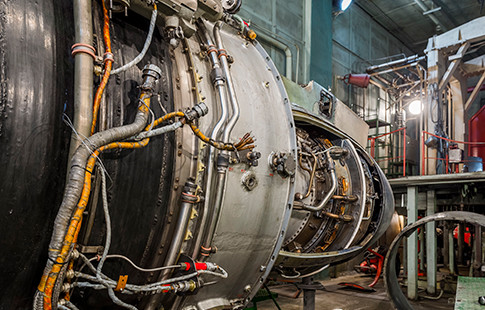

Challenge: Requirement for strain measurements in high temperature environments.

Solution: High temperature bonding applications are a common requirement and challenge for many strain gage manufacturers. Our high-precision strain gages are produced in-house and capable of operating reliably in temperatures in excess of 1,000°C.

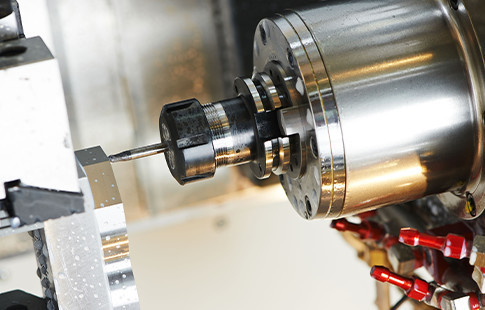

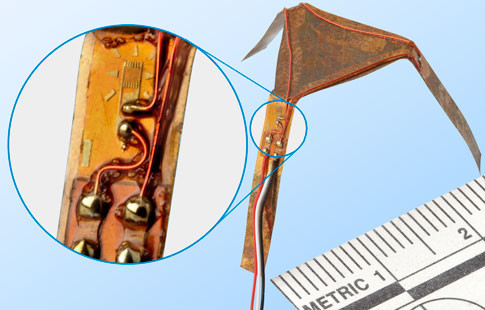

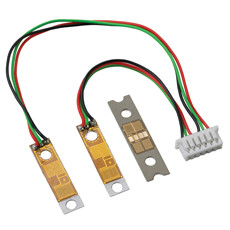

Challenge: Ultra-miniature strain gage installations with grid sizes as small as 0.5mm x 0.5mm require specialty equipment and experience.

Solution: We have been creating many such unique installations for customers for many years. Typical installations include quarter-bridge strain measurement and full Wheatstone bridge configurations measuring force.