Helping to feed a hungry world

VPG Force Sensors is a world leader in advanced strain gage technology and custom solutions for agriculture equipment. Our extensive experience and expertise enable us to design the best solution for your unique requirements.

Challenge: Lack of visual on load attachment behind tractor

Solution: VPG Force Sensors designed a hitch sensor that provides feedback to the tractor operator. This valuable feedback informs the operator when it is time to unload the harvest or if there's a technical glitch with the attachment. Our solution helps farmers achieve a good yield and keep the tractor and attachment operating with maximum efficiency.

Challenge: Accurate soil depth and spacing for seed planting.

Solution: VPG Force Sensors designed a force sensor that enables the equipment to accurately prepare the soil and plant the seeds at the right depth and spacing. This cost-effective and efficient solution helps increase yield.

Challenge: Analyze grain yields in different areas of the field.

Solution: VPG Force Sensors custom-designed a single point load cell and software algorithm that allows famers to communicate with the load cell using the CAN bus communication protocol. The load cell collects force readings created by the grains collected in the storage tank, enabling farmers to analyse the condition of the field and make adjustments to maximize yield.

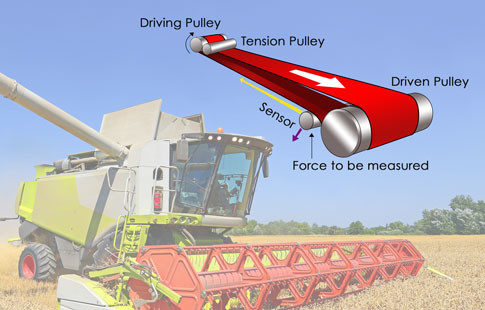

Challenge: Downtime to maintain a harvester is expensive. One cause of downtime is jamming of the harvester's drums.

Solution: VPG Force Sensors helped to eliminate the drum jams and helped save money by designing a sensor that tracks the tension on the harvester's belt. The operator is alerted before the tension reaches a dangerous level, avoiding the jam and possible permanent damage.